Your cart is currently empty

How to Tan Leather like The Tanneries

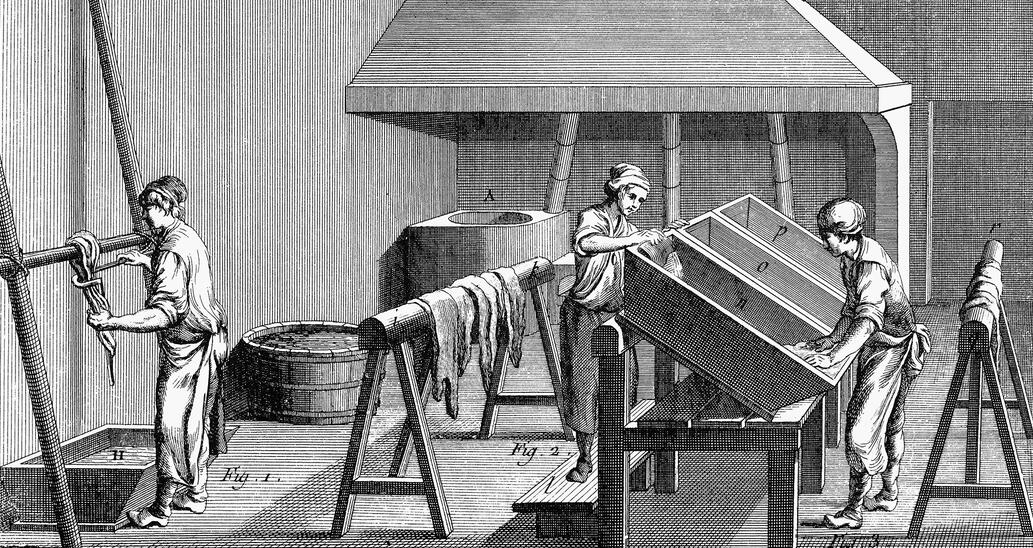

Have you ever wondered how the leather of the product you buy is made? All leather is produced through many processes, including tanning, dyeing, drying, and curing. We will examine the tanning process to understand why the type of tanning applied to the hides has such a significant effect on the final product.

Why is leather tanning necessary?

The leather must be tanned otherwise, the rawhide will rot and rot. The tanning process prevents rotting by stabilizing the proteins in the rawhide or hide, preparing it for a wide range of end uses. The main difference between dry-tanned leather and rawhide is that tanned leather does not deteriorate when exposed to moisture. The appearance of leather changes with tanning. The time it takes and the tanning substances used to determine the change.

How to clean leather prior to tanning

Animal hides go through several stages before they are ready to be tanned and used to make products such as belts, bags, shoes, furniture, and clothing. Fleshing, preserving or curing, soaking, sanding, hair-splitting, splitting, descaling, beating, reducing, bleaching, stripping, and pickling are some of the steps that precede tanning. The next step is to skin the leftover meat once it comes out of the farm or slaughterhouse.

The skins are then salted to dry them. Curing prevents rotting by stopping the growth of bacteria on the skin between purchase and processing. Wet salting, where the hides are salted liberally and then compressed into bundles for up to 30 days, is a method of drying the hides. Another method is to soak them in a saltwater solution for about 16 hours.

Banking is the procedure that follows curettage.

The curing process removes residual salt in the first stage, called soaking. To avoid the development of bacteria and fungi, this technique consists of soaking the skins in water containing specific chemical products.

After soaking, the hides and skins are whitewashed. It consists of soaking the skin in an alkaline solution, milk or lime, in a well or a drum. Waxing removes natural keratin, hair, fats, and lipids. Moreover, it induces the right degree of fiber swelling and splitting and brings the skin's collagen to a perfect state for tanning.

The skin is then passed through a machine after the application of lime to remove the fleshy tissue from the meat side. The act of fleshing involves the removal of connective tissue and meat by-products from the fleshy side of the hide. Rotating scraper rollers are used.

Grooming is followed by waxing, which is exactly what it sounds like: the process of removing hair from the skin. Most hair is removed after using unwanted treatments such as calcium hydroxide and sodium hydroxide, first mechanically and then manually with a dull knife.

The next step is liming, which involves adding acid to the hides in a drum or pit to reduce their alkalinity. In preparation for the striking process, the expanded skin fibers are shrunk again. For cattle hides, the deliming process can take up to two hours.

Hides can be beaten depending on the use of the leather. In the "baiting" process, enzymes are added to the skins to soften them.

How is tanning for leather working?

Leather is prepared by tanning leather. Here are the stages of leather tanning, depending on the type and destination of the leather:

Soaking

Soak the item to remove any excess dirt or salt. To ensure clean, flat strips are created, all non-leather components must be removed from the skins.

Lime

Liming is a process of adding alkali to hides to separate fibre bundles and remove excess hair. Hair-sparing or partially hair-sparing systems give excellent results. Usually, lime is added here before sodium sulfide, and sodium hydrosulfide is added later, causing alkaline swelling. This allows the lime to disperse evenly and penetrate the granules, resulting in the best fiber splitting and separation possible. The skin is now often referred to as fur.

D-lime

After fleshing and/or splitting, hides require complete deliming and neutralizing of any remaining alkalinity. The most effective way to achieve this is to use special organic acids and acid salts which produce highly soluble lime complexes. Due to the rapid decrease in pH of the float, special care must be taken to effectively buffer the descaling bath and prevent the precipitation of soluble proteins.

Now, by the prolonged activity of the appropriate enzyme preparation, the network of elastin fibers, which are insoluble under the extremely alkaline conditions of lime, should be loosened and uniformly flattened.

Strip

Stripping acid is applied to soften the skin and improve the penetration of the tanning agent.

Sun tanning

The use of a tanning agent modifies the collagen structure of a hide, and it is converted into an intermediate form of leather. The material is now flexible and impervious to chemicals, moisture, and bacteria.

Where does the word "tan" come from?

Traditionally, hides were turned into the leather using a chemical called tannin. The bark of certain types of trees was used to produce tannins. In the 1800s, alternative techniques were created when using chrome salts and chrome tanning instead of natural tannins. Zeolite tanning is better for the environment than chrome tanning and is one of many options available today.

The chemicals used in tanning can be classified into four groups

- Sunbathe with plants

- Chrome tanning

- Aldehyde-free and chrome-free tanning

- Geology: Tanned with zeolite

Sunbathe with plants

The oldest tanning technique is vegetable tanning. It uses tree and shrub nuts and wood extracts. These come from a sustainable source, thanks to responsible sellers. This approach generally takes longer to tan the leather, but the end product has a distinctive look and holds up well to aging.

Vegetable-tanned leather may seem more "eco-friendly" depending on its name and the tanning substances used. To make a more relevant comparison with other approaches, one must consider the overall balance throughout the process. For example, chrome-tanned leather requires several times more tannin than vegetable-tanned leather. Also, additional processing is required before releasing the generated stream. It has the advantage of using natural, sustainable, and renewable raw materials.

Chrome tanning

Most of the leathers produced today are chrome tanned, about 75%. The process uses trivalent chromium (Cr III), a harmless chemical. Chrome tanning creates a uniform leather that retains its properties at all times and can be worn or worn. Hexavalent chromium, often called chromium VI (Cr VI), is said to be used for tanning leather and is dangerous. Chromium VI is not used in leather production. The chrome tanning process is always improving as its absorption increases, less is used, much is recycled, less water is needed, and waste is carefully managed. The chemicals used in chrome tanning cause damage to the ecology.

Aldehyde-free and chrome-free tanning

There are other tanning techniques, each with its own name. They are usually classified and referred to as "chrome free." Chrome-free leathers are usually produced to meet a specific performance requirement or are often intended for automotive use. Aldehyde tanning, which uses glutaraldehyde, is the most popular. Many other chemicals are needed after tanning to improve the properties of leather made using this tanning process. This means that the glutaraldehyde-based chromium-free process stream must undergo additional treatment before it can be discharged.

Geology: Tanned with zeolite

The use of zeolites in chemical tanning technology is a recent development. Zeolites have an unusual ability to release or absorb water depending on the temperature. The comfort of leather depends to a large extent on its ability to absorb water, so a desirable quality in tanning is one that allows water absorption without swelling. The zeolite-based tanning does not diminish the performance of the leather and is free of heavy metals, aldehydes, and chromium.

What happens when you tan the hide?

The hide's protein structure is permanently changed during the tanning process, making the leather stronger and more resistant to deterioration and fading. The hides are detailed, degreased, desalted, and soaked in water for two to six days before tanning.

How is skin usually tanned?

Historically, tanning involved the use of tannin, an acidic chemical derived from the bark of certain plants that gives the tanning process its name. The 1800s saw the development of chrome tanning, an alternative process that substituted natural tannins for chrome salts.

How long does skin tanning last?

Wet salting involves severely salting the hides before pressing them into bundles for about 30 days. Brining involves soaking the skins in a saltwater bath for approximately 16 hours. Hides and skins can also be stored at extremely low temperatures for hardening.

How were furs banned by Native Americans?

The skin was rubbed with a mixture of brains, liver, soap dish, and tanning grease. The tan softens it. During the slaughter of buffaloes, women played an important role. After the animal is skinned, the skin is spread out and nailed to the ground to spread out and dry.

What types of leather are sold?

After tanning, the leather is prepared and sold to buyers. The leather industry describes and measures many ways in which leather is sold using specific terms. The side, the leather, the skin, the crust, or the belly belong to it.

The size of the product varies depending on the size of each side, leather, skin, neckline, and abdomen. While thickness is sometimes measured in millimeters and/or ounces, measurements are sometimes made in square feet or square meters. Since leather is divided into different thicknesses with specific weights, converting width to weight is straightforward. Leather scraps are generally sold by weight.

Environmental issues

Historically, leather tanning processes involved organic resources such as tree bark and leaves. As the tanning of this type of vegetable only requires water, which is then discharged into rivers or lakes, the environmental impact is reduced. The effluent does not pollute since it ends up decomposing in the water because it is organic.

Similarly, brain tanning tans leather using the acids and fats of the animal's brain, with water consumption being the only downside. Again, the biodegradable material poses no risk to the environment.

In contrast, chrome tanning uses many potentially toxic chemicals that often pollute the air, soil, and water. Effluent treatment is required in many countries, but in poorer countries, regulations are often flouted, leading to excessive pollution levels around tanneries. The methods used in tanneries produce a characteristic smell, which is why they are usually associated with a very strong smell. This meant that, historically, tanneries spread throughout communities and towns. Tannery workers are more susceptible to cancer and other illnesses due to the chemicals they are exposed to.

Can leather be recycled?

Like any mass-produced product, leather production has the potential to have a negative environmental impact. However, there are more environmentally friendly methods of making leather. The environmental impact is greatly reduced by producing it to order, using by-products from meat and dairy farms, and avoiding using harmful chemicals for tanning the leather. Vegetable-tanned leather is the most eco-friendly leather you can buy because it is natural and not synthetic.

Besides using chromium during the tanning process, the amount of water required for tanning is the main environmental impact of leather. However, since there is a meat and dairy industry, the alternative to turning hides into leather has been to send them to landfills. This industry is vital to the livelihood of communities around the world. By turning these hides into the leather to make products like bags and jackets, the waste from these companies is greatly reduced.

The use of synthetic materials derived from fossil fuels such as petroleum, such as PVC, is the biggest negative environmental impact associated with vegan leather. One of the biggest contributors to the negative environmental impacts of fast fashion is the use of synthetic materials. The faux fur industry also has additional negative effects on the environment, such as wasted water and sometimes toxic dyes. New developments in more environmentally friendly leatherette products made from cork or pineapple leaves are constantly being made. However, these lack the strength and durability of genuine leather and still rely on plastic-based adhesives to hold the fibers together.

Genuine Leather vs. Vegan Leather

As the need to address climate change grows, more and more people are considering sustainability when making day-to-day decisions. Today, many fashion retailers offer sustainable ranges, and the market for products such as eco-leather bags continues to grow. The term "vegan leather" (sometimes called "faux leather") tends to be misleading because it suggests the material is durable. This is not really the case, as synthetic materials like PVC and PU are widely used to make faux leather. Synthetics don't biodegrade and spend a lot of time in landfills after disposal.

Yes, you can take care of the item and keep it safe for a long time without throwing it away. Additionally, there are increasing opportunities to recycle and reuse discarded products, all of which help reduce the carbon footprint. Some might say that buying a leatherette bag from a major retailer is far worse than supporting local businesses that make real leather using a more environmentally friendly process, like vegetable over chrome.

Plus, genuine leather is more flexible than fast-fashion vegan options. Fast fashion is meant to be edgy and disposable. Because they are so inexpensive and often made from synthetic materials, maintaining them requires more effort than buying new ones. What if it breaks and you can't give it away? In the UK alone, over a million kilograms of fabric go to landfill every year. Leatherette bags will cost the environment (and your wallet) more in the long run due to the number of bags that need to be replaced over the life of a genuine leather bag. Genuine leather is better than vegan leather for another reason: over time, it will take on a more authentic and unique look. With full-grain and vegetable-tanned leather, this is more common. The inevitable patina of a leather bag only makes it better; Vegetarian options will not follow.

Conclusion

As we have seen, tanning is an important step in manufacturing leather. Although it goes through several stages, each helps create the polish and other characteristics that make leather attractive. The leather produced will come in various prices, colors, thicknesses, and qualities, as there are many tanning techniques, from brain tanning to chrome tanning. Now that you know more, it should better equip you to choose a leather tanning method.

Shop our collection of:

Men's Leather Duffle Bags | Men's Leather Backpacks | Men's Leather Laptop Bags | Men's Leather Briefcases | Women's Leather Duffle Bags | Women's Leather Backpack Purses | Women’s Leather Laptop Bags | Women's Leather Briefcases

Related Blog Posts: